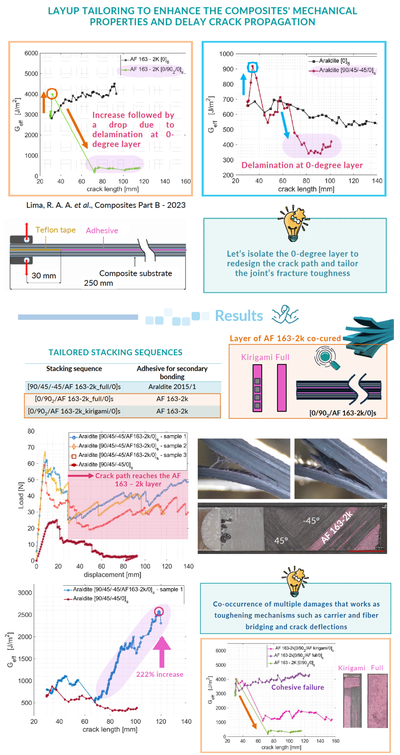

Tailoring Composite Substrates

@Técnico @TU Delft

Efforts to reduce CO2 emissions and improve sustainability in the aeronautical sector have been increasing, leading to new solutions to extend aircraft’s operational life and reuse of multi-material and composite components. Furthermore, the industry is striving towards more efficient, sustainable, and lightweight aircraft. However, one of the challenges that needs to be tackled is the assembly and repair of advanced material components in primary structures.

This project aims to enhance the damage tolerance of secondary adhesively bonded joints by architecting their CFRP layups and exploring the effects of adhesives with different fracture toughness.

Researchers:

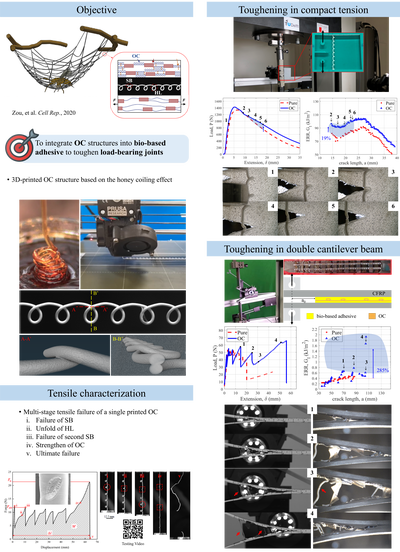

Biomimetic Toughening Structures

@TU Delft

Climate change is a major global issue that impacts both the environment and human society, requiring an immediate effort to enhance sustainability in the mobility and energy sectors. Adhesive joints of lightweight composite structures offer great potential for more efficient and environmentally friendly designs, but ensuring their safety and reliability remains a major challenge.

Drawing inspiration from the molecular design of spider silk, the project explores 3D-printed polymeric structures that incorporate sacrificial bonds and hidden lengths. When embedded in polymer resins, these overlapping curl structures enhance the toughness of layered materials and create a supporting framework that enables alternative load paths, paving the way for safer and more sustainable lightweight structures.

Researchers:

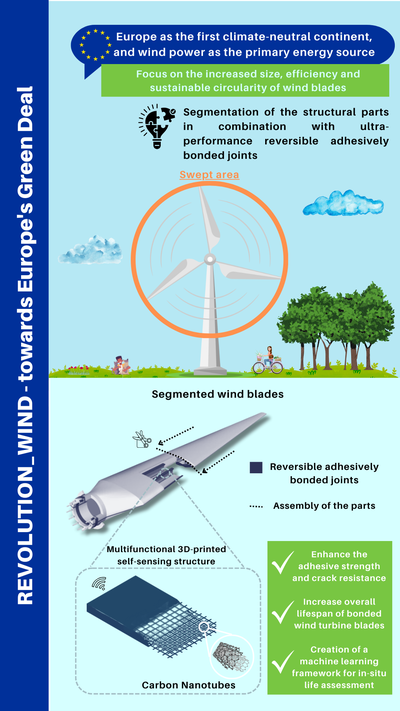

REVOLUTION_WIND

REVOLUTIONising WIND blade life-cycle through circular design and Condition-Based Monitoring using multifunctional self-sensing 3D printed bonded structures and a multi-modal machine learning approach

@Técnico

The challenge of climate change poses a significant threat to humanity. It is essential to prioritise renewable and cost-effective energy sources while simultaneously reducing greenhouse gas emissions for the benefit of future generations. One of the primary solutions lies in the new generation of larger, segmented and more efficient wind blades.

The REVOLUTION_WIND project aims to enhance the circularity and damage tolerance of the new generation of larger and segmented wind blades by embedding a multifunctional self-sensing 3D printed structure within a reversible adhesive layer. The project will use a combination of supervised machine learning and experimental characterisation to devise a multi-modal monitoring system that can accurately predict the remaining useful life of the reversible adhesively bonded joints. The most cutting-edge outcome of REVOLUTION_WIND is a multifunctional 3D printed self-sensing structure that will work as an embedded reinforcement and generate input data for a machine learning framework for in-situ life assessment of the structural integrity of reversible adhesively bonded joints.

Finally, the successful implementation of REVOLUTION_WIND will contribute to achieving the European Green Deal’s objective of establishing wind power as Europe’s primary energy source while promoting a circular economy.

Funding Scheme:

HORIZON-TMA-MSCA-PF-EF - HORIZON TMA MSCA Postdoctoral Fellowships - European Fellowships

Useful link: https://cordis.europa.eu/project/id/101153013

Researchers:

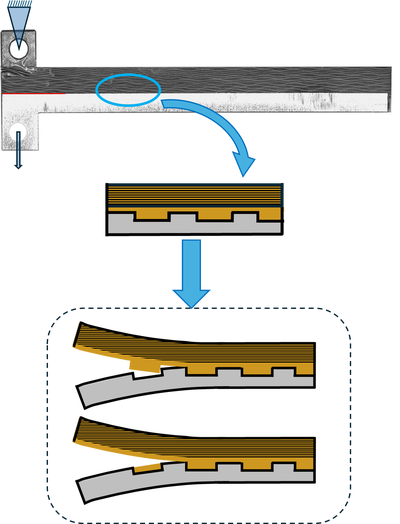

Metal-to-composite Interfaces

@TU Delft

Aerospace and automotive industries are under increasing pressure to reduce product weight in response to strict environmental regulations and the demand for lower operational costs. Adhesively bonded lightweight composites offer a promising route toward more efficient and sustainable designs. However, their safe and reliable application remains a key challenge.

This project develops innovative methods for fracture characterization of bi-material bonded joints, with a particular focus on metal-to-polymer interfaces. By uncovering the underlying interfacial mechanisms, the research supports the reliable integration of composites with conventional metal-based structures, enabling stronger, lighter, and more sustainable engineering solutions.

Researchers:

Main Past Projects

- European Cooperation in Science and Technology - COST CERTBOND – Reliable roadmap for certification of bonded primary structures. 2019-2023. https://www.certbond.eu/

- Interreg 2 Seas Mers Zeeen - European Regional Development Fund - QUALIFY: Enabling Qualification of Hybrid Structures for Lightweight and Safe Maritime Transport. 2018-2022. www.tudelft.nl/ae/qualify

- NWO, Dutch Science Foundation, Individual grant of Talent Scheme VENI - Flybond: Novel design concept for composite bonded joints. 2016-2020

- NWO, Dutch Science Foundation, High Tech Materials - Durabond: Durable composite-to-metal bonded joints for heavily loaded structures at extreme environmental conditions. 2016-2020.

- RVO, Dutch Enterprise Agency, Compact Solar: Solar Panels. 2018-2020.

- HORIZON 2020, CleanSky2, European Union - TICO-AJO: TItanium COmposite Adhesive JOints. 2016-2018

- HORIZON 2020, European Union - EFFICOMP: Efficient Composite parts manufacturing. 2016-2020.